TOSCCO Raw Material

Tag Pin Raw Material 1:

We Use PP (polypropylene), due to the following characteristics of PP, it is very suitable for us to manufacture tag pins: heat resistance, with a melting point ranging from approximately 160 to 170°C, low density, around 0.90-0.91 g/cm³, mechanical tensile strength, chemical stability, transparency, and Eco-friendliness. Making it an ideal material for us to produce tag pins.

Tag Pin Raw Material 2:

Due to the high tensile strength and fatigue strength of Nylon 66, we can better serve customers with high strength and tensile requirements. With heat resistance up to 265°C, excellent chemical stability, and dimensional stability, we can produce high-quality Nylon tag pins.

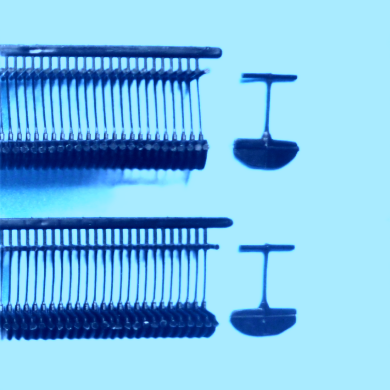

Tag Pin Mould Raw Material:

We usually use S136 (Stainless Steel), S136 has excellent corrosion resistance and polishing performance, as well as good anti-adhesion properties. It is highly corrosion-resistant and provides a high surface quality, making it suitable for the processing and production of various tag pins, medical devices, and military products.

We can also use steel P20, P20 steel is suitable for batch production. It is ideal for tag pin molds with various shapes and high precision requirements.

We can also use customized or imported steel to meet the specific requirements of your high-precision plastic injection molds.